Germany - Dismantling two Frigoscandia GyroCompact GC42 Spiral Freezers

Our partner asked us to complete the dismantling of these two Frigoscandia GC42 Spiral Freezers

Germany - Dismantling Frigoscandia M7 Spiral Freezer

Frigoscandia / JBT Foodtech M7 Spiral Freezer

This used Frigoscandia M7 was in excellent condition when Industrial Freezing purchased the freezing equipment in th…

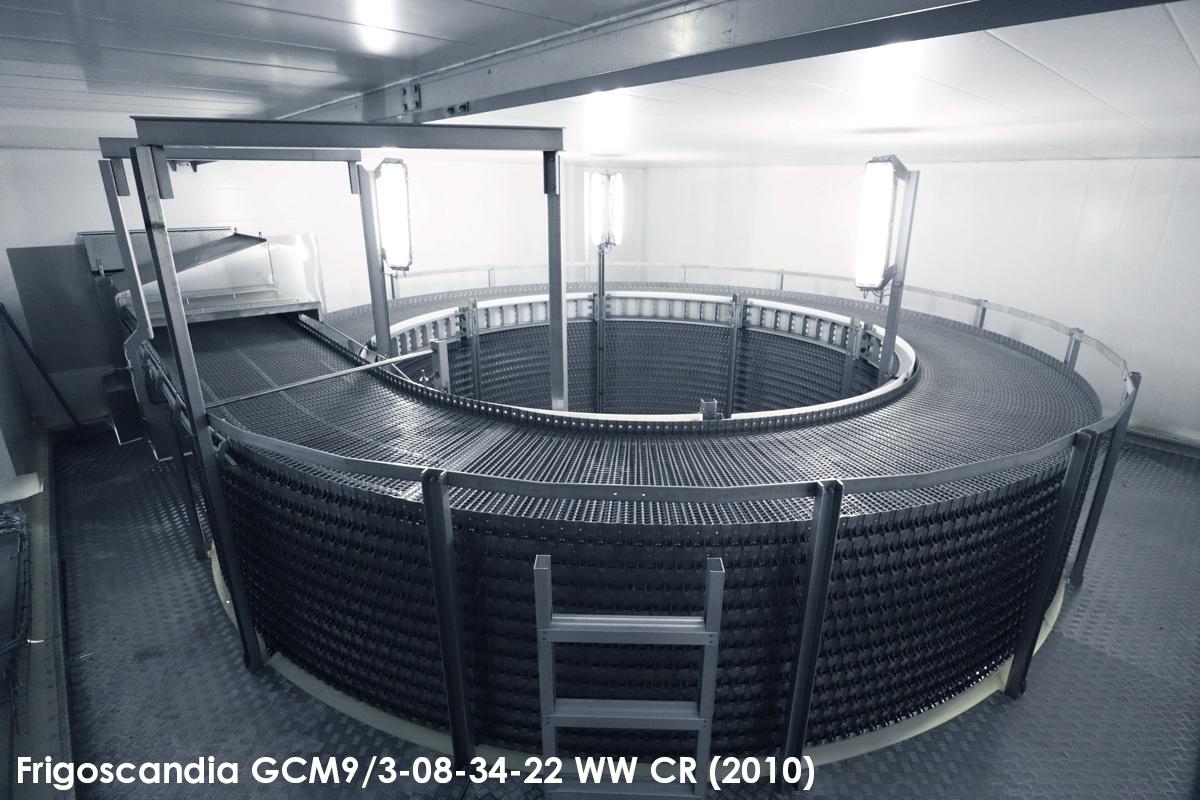

Luxembourg - Frigoscandia GCM106 Spiral Freezer

This Frigoscandia GYRoCOMPACT M106–08–36–40 EE CCR Spiral Freezer was the first of four Frigoscandia spiral freezers

that Industrial Freezing® dismantled at a former conv…

Four Frigoscandia Spiral Freezers in Luxembourg

These four spiral freezers are currently being removed from its previous location in Luxembourg, where they have been used for the processing of several different dough products, like past…

Germany - Frigoscandia GCM7 Spiral Freezer

This extremely well-maintained 2013 Frigoscandia GYRoCOMPACT M7 Spiral Freezer is the latest addition to our pre-owned freezer range. It has been used for freezing freshly baked bread and …

ABOUT DISMANTLING (SPIRAL) FREEZERS

First and foremost, it is up to the Industrial Freezing® purchasing team to conclude an agreement with a supplier about the purchase of a used installation. After the purchasing contract is signed by both parties, the planning phase for the Industrial Freezing® dismantling team starts.

We start off with a visit on location with the project coordinator and dismantling foreman. Here, we carefully observe the location, the production environment and all electrical cabling. We thoroughly inspect the installation itself and photos are being taken. The first sketch of an action plan is ready. Returning to the office, we allocate our people, dismantling equipment and transport. The project plan will be prepared, as well as the health and safety plan for the job on location.

“At Industrial Freezing®, we believe that good preparation is half the job.”We believe that a safe execution is the most important factor in the process. The Industrial Freezing® dismantling team adheres to our own comprehensive health and safety rules, while abiding to the house rules of the client at the same time. Our dismantling foreman supervises the job and ensures everything is proceeding according to the plan.

We ensure limited disruption in the current production process, if at all. Our technicians are disassembling and installing various types of cooling and freezing installations on a daily basis, in both our own workshop and on location. Matchmarking ensures we know exactly which parts go where and ensures a flawless installation in the future, especially after overhauling the complete installation. Go to our Repairing project page to learn more about how we overhaul our freezing and cooling equipment.